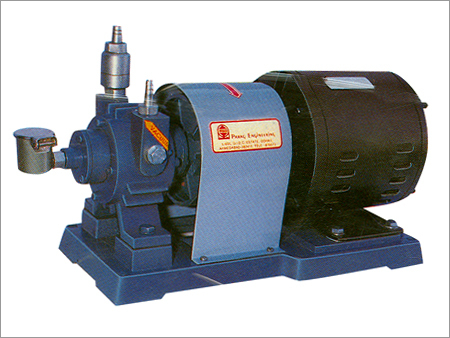

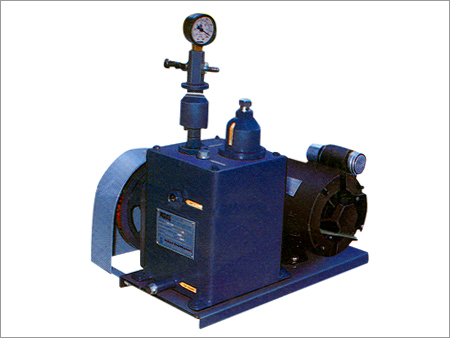

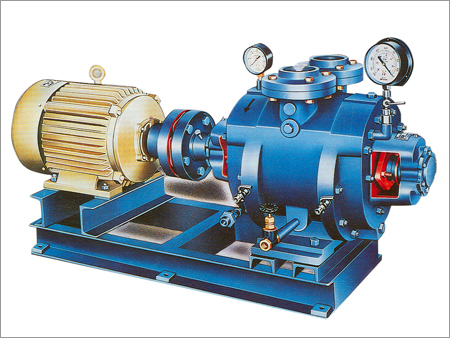

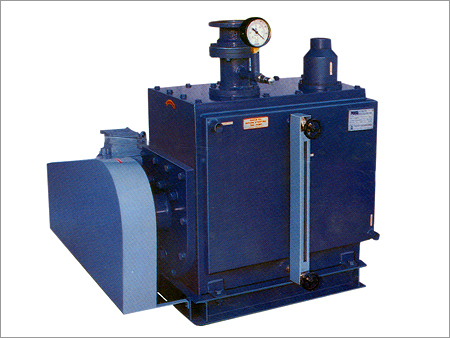

Vacuum Cum Pressure Pumps

Product Details:

X

Product Description

Vacuum cum Pressure Pump:

| Model No. | Free Air Displacement | Ultimate Vacuum Inch of Hg. | Pressure PSIG | Motor Reqd. H.P. | |

| Lt./Min. | C.F.M. | ||||

| DA-75 | 75 | 2.5 | 28" | 10 | 0.25 |

| DA-150 | 150 | 5.3 | 28" | 10 | 0.5 |

| DA-300 | 300 | 10.6 | 26" | 10 | 0.75 |

| DA-500 | 500 | 17.5 | 26" | 10 | 1.0 |

These are combined Vacuum-cum-Pressure pumps, designed and manufactured for long trouble free operating life. These are basically air-cooled, rotary pumps. Being compact, light weight and easily assembled, they required minimum attention even in continuous operation. Accessories like Vacuum and pressure regulators. Vacuum and pressure gauges, relief valves, inlets filter, exhaust oil beffle etc. are available for different models.

Applications:

- Vacuum lifting

- Paper and Lable handling in printing and labling machine

- Evacuation of containers in food-packing

- Vacuum forming

- Air stampling

- Bottle filling

These are of oil-immersed, rotary vane type pumps. The rotor, with two spring loaded vanes, is mounted eccentric in the stator body. As the rotor, rotates the vanes sweep the crescent shape air space twice in each revolution. There is in-built non-return valve which prevents back flow of air.

Manufactured from graded material, all moving parts are precisely machined, ground and assembled with close tolerances. This results in increased efficiency and long trouble free operating life.

Accessories:

Air Ballast:

This is a vent pipe introducing air before actual compression which eliminates condensation of the sucked vapour, there by avoiding contamination of oil.

Air Admittance Valve:

It is electromagnetic solenoid type which admits air into the system as soon as the power supply fails. This prevents back-flow of oil to the system.

Non-Return Valve:

It is rubber diaphragm type, spring loaded valve, which prevents back-flow of oil to the system as soon as pump stops. These can not be used to hodl the vacuum in the system for longer period.

Manufactured from graded material, all moving parts are precisely machined, ground and assembled with close tolerances. This results in increased efficiency and long trouble free operating life.

Accessories:

Air Ballast:

This is a vent pipe introducing air before actual compression which eliminates condensation of the sucked vapour, there by avoiding contamination of oil.

Air Admittance Valve:

It is electromagnetic solenoid type which admits air into the system as soon as the power supply fails. This prevents back-flow of oil to the system.

Non-Return Valve:

It is rubber diaphragm type, spring loaded valve, which prevents back-flow of oil to the system as soon as pump stops. These can not be used to hodl the vacuum in the system for longer period.

- Moisture Trap, Inlet Dust Filter, Vacuum Gauge with Regulator, Trolly for small Pumps.

- USE Oil: ENCLO - 46 (HP) SAE - 30 or Equivalent Vacuum Oil.

- Model HL - 300 - II and above, are provided with water cooling jacket.

- Vacuum Measured Mcleod gauge at suction port of the pump.

Applications:

- Distillation

- Dehydration and filtration processes

- Exhausting Electronic Tubes

- GLS Lamps

- Mercury Vapour Lamps and Tubes

- Vacuum metallurgy

- Vacuum Sublimation

- Vacuum impregnation

- Thin film coating

- Refrigerator and Air conditioner servicing

- Freeze drying of foods.

Other Products in 'High Vacuum Pumps' category

PARAG ENGINEERING

PLOT NO- L-605, G.I.D.C. Estate, Odhav,Ahmedabad - 382415, Gujarat, India

Phone :View Number

|

|

|

|

PARAG ENGINEERING [3175][Ahmedabad]

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |