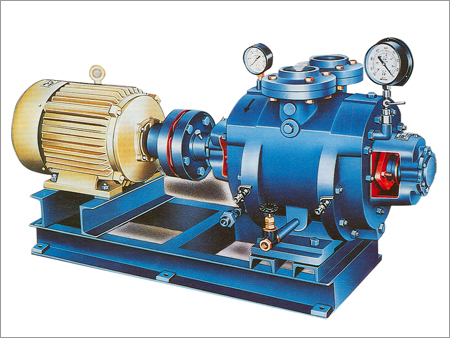

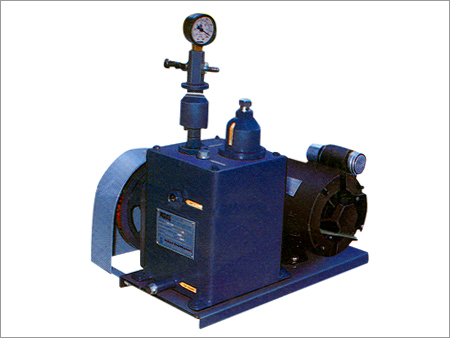

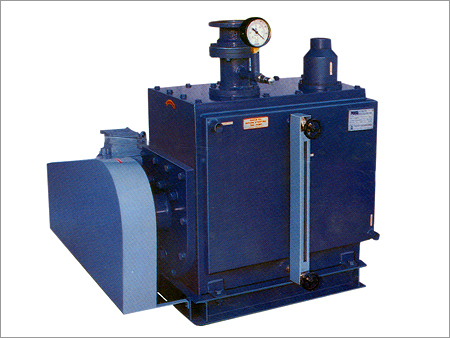

Water Ring Vacuum Pumps Compressors

Product Details:

X

Product Description

Water Ring Vacuum Pumps Compressors:

| Model No. | Free Air Displacement | Ultimate Vacuum Inch of Hg. | Pressure PSIG | Motor Reqd. H.P. | |

| Lt./Min. | C.F.M. | ||||

| DA-75 | 75 | 2.5 | 28" | 10 | 0.25 |

| DA-150 | 150 | 5.3 | 28" | 10 | 0.5 |

| DA-300 | 300 | 10.6 | 26" | 10 | 0.75 |

| DA-500 | 500 | 17.5 | 26" | 10 | 1.0 |

- Entrained liquid drops, Condensable vapours or occasional slugs of liquid can be handled without damage to the pump or significant effect on capacity. In the case of vapours, the pump can also serve as a condenser.

- No lubricant or oil is required within the pump itself. Thus the air or other discharge gases are not contaminated. The liquid which forms the ring (usually water) serves both as a sealant and a pumping media.

- A wide selection of materials and seal liquids can be used when corrosive gases and vapours are being pumped.

- The pumps contain no metal parts that rub against each other. Packing glands and bearings are accessible from the outside. There is no clearance volume and the pumping action is smooth and uniform (non-pulsating).

- The only moving part is a balanced impeller which reduces noise and vibration. This means lower foundation, installation and service costs.

- The pump can be provided with partial liquid recycle, closed loop liquid operation, automatic control and other features.

- Mechanical seals can be provided as an option.

- Small entrained solid will pass through the pump. However, abrasive particles will result in reduced pump life.

- Each pump is performance tested prior to shipment.

Applications:

The applications for liquid ring vacuum pumps are diversified and include druing condensing, distilling, impregnating, sterilizing, evacuating, cooking, evaporating, draining, conveving, venting and sucking. Liquid ring vacuum pumps are being used in the chemical, petrochemical, Pharmaceutical, pulp and paper and food industries.

Some Specific Applications are:

The applications for liquid ring vacuum pumps are diversified and include druing condensing, distilling, impregnating, sterilizing, evacuating, cooking, evaporating, draining, conveving, venting and sucking. Liquid ring vacuum pumps are being used in the chemical, petrochemical, Pharmaceutical, pulp and paper and food industries.

Some Specific Applications are:

- Draining paper webs

- Saturating insulation materials, wood and textiles

- Evacuating condensors and piping

- Priming pumps

- Evaporating acids, blood and milk

- Drying resins, paints and chemicals

- Conveving wheat, sugar and chemical products

- Lifting and transporting wood and plates.

Operating Principle:

The working parts of the Parag Pumps cossets of amulti-vane impeller mounted eccentrically in a round casing which is partly filled with liquid (usually water). As the impeller rotate the liquid is thrown by centrifugal force to from a liquid ring which is connector with the periphery of the casing. Due to the eccentric position of the impeller relative to the casing and liquid ring the spaces between the impeller vanes fill with liquid during rotation and any air or gas trapped in the impeller space or cell is compressed and discharged from the casing through the outlet part leaving the cell available to receive air or gas as it is presented to the inlet port of the casing. In addition to being the compressing medium the liquid ring performs three other important functions. It absorbs the heat generated by compression nd friction.

It absorbs any liquids slugs or vaporu entering with the gas stream.

It will also absorb and wash out contaminants entrained in the gas.

Wide Choice of Materials:

Standard materials of construction is cost iron with semisteel rotor. Shaft material is stainless steel for model PW - 1 to PW - 4, larger sizes are carbon steel with brass of stainless steel shaft sleeves for wetted parts.

Alternate combination materials are available for special applications.

The working parts of the Parag Pumps cossets of amulti-vane impeller mounted eccentrically in a round casing which is partly filled with liquid (usually water). As the impeller rotate the liquid is thrown by centrifugal force to from a liquid ring which is connector with the periphery of the casing. Due to the eccentric position of the impeller relative to the casing and liquid ring the spaces between the impeller vanes fill with liquid during rotation and any air or gas trapped in the impeller space or cell is compressed and discharged from the casing through the outlet part leaving the cell available to receive air or gas as it is presented to the inlet port of the casing. In addition to being the compressing medium the liquid ring performs three other important functions. It absorbs the heat generated by compression nd friction.

It absorbs any liquids slugs or vaporu entering with the gas stream.

It will also absorb and wash out contaminants entrained in the gas.

Wide Choice of Materials:

Standard materials of construction is cost iron with semisteel rotor. Shaft material is stainless steel for model PW - 1 to PW - 4, larger sizes are carbon steel with brass of stainless steel shaft sleeves for wetted parts.

Alternate combination materials are available for special applications.

| Model No. | Suction | ELE. Motor | Water | Suction | Water Conn. | A | B | C | D | E | F | G | H | J | L | M | |||

| M3/Hr. | CFM. | H.P. | R.P.M. | Lt./Min. | K∅ | N.B. | |||||||||||||

| PW-2 | 50 | 30 | 3 | 2880 | 7 | 25 | 1" | 1/2" | 380 | 245 | 120 | 130 | 250 | 750 | 240 | 72 | 75 | 100 | M10 |

| PW-3 | 80 | 50 | 5 | 2880 | 10 | 30 | 1.1/4" | 1/2" | 425 | 245 | 120 | 130 | 265 | 900 | 230 | 85 | 90 | 120 | M12 |

| PW-4 | 120 | 75 | 7.5 | 2880 | 14 | 36 | 1.1/2" | 1/2" | 465 | 245 | 120 | 130 | 265 | 1100 | 260 | 95 | 100 | 130 | M12 |

| PW-5 | 160 | 95 | 7.5 | 1440 | 15 | 50 | 2" | 1/2" | 655 | 440 | 220 | 200 | 400 | 1200 | 360 | 150 | 120 | -- | 4x16 |

| PW-6 | 220 | 130 | 10 | 1440 | 20 | 60 | 2.1/2" | 3/4" | 690 | 440 | 220 | 200 | 400 | 1300 | 380 | 150 | 120 | -- | 4x16 |

| PW-7 | 330 | 195 | 15 | 1440 | 30 | 80 | 3" | 3/4" | 785 | 440 | 220 | 200 | 420 | 1400 | 450 | 190 | 150 | -- | 4x20 |

| PW-8 | 440 | 260 | 20 | 1440 | 40 | 80 | 3" | 3/4" | 855 | 440 | 220 | 200 | 420 | 1500 | 480 | 190 | 150 | -- | 4x20 |

| PW-9 | 720 | 410 | 30 | 980 | 60 | 125 | 5" | 3/4" | 920 | 650 | 320 | 290 | 540 | 2100 | 510 | 240 | 200 | -- | 8x20 |

| PW-10 | 845 | 490 | 35 | 980 | 80 | 125 | 5" | 3/4" | 980 | 650 | 320 | 290 | 540 | 2200 | 550 | 240 | 200 | -- | 8x20 |

| PW-11 | 1080 | 650 | 40 | 980 | 100 | 125 | 5" | 3/4" | 1060 | 650 | 320 | 290 | 540 | 2300 | 590 | 240 | 200 | -- | 8x20 |

Other Products in 'High Vacuum Pumps' category

PARAG ENGINEERING

PLOT NO- L-605, G.I.D.C. Estate, Odhav,Ahmedabad - 382415, Gujarat, India

Phone :View Number

|

|

|

|

PARAG ENGINEERING [3175][Ahmedabad]

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |